CN ▏ENWelcome to visit JACK ARTIFICIAL LIFT MACHINERY CO., LTD the official website!

Production Site

Contact Us

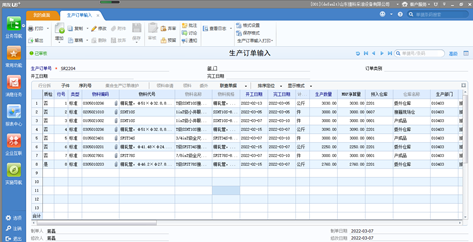

We currently have 8 standardized workshops, with four production plants: pumping unit factory, sucker rod factory, core component factory, PCP/DHP/HPU factory, with an annual output of 2,500 sets of pumping units and reducers, 1 million sets of sucker rods and couplings, 2,000 sets of pumping pumps, 1,500 sets of drive heads, 200 sets of hydraulic pumping units and 3,000 sets of PCP rotors ability. The ERP system covers the entire production process management. Production order scheduling, procurement plan issuance, and semi-finished product management are all completed by relying on the ERP system to ensure the timeliness of production delivery and refined on-site management.

We adhere to the quality policy requirements of "people-oriented, lean production, quality first, continuous improvement, customer satisfaction", and convey the company's quality policy to the management, execution, verification and operation levels to ensure that everyone understands and implements it, and then guarantees Product quality is controllable.

Packing workshop of pumping unit factory Test workshop of pumping unit factory

The unloading workshop of the pumping unit factory Riveting and Welding Workshop of Pumping Unit Factory

Core component factory processing workshop Reducer assembly workshop of PCP factory

Drive head assembly workshop of PCP factory Sucker Rod Factory

ERP system